Wood flooring comes in different shapes and sizes and some formats are better suited to certain situations than others.

Solid Oak Flooring

A solid wood floor is essentially a piece of a tree that has been sliced, dried in a kiln (to moisture levels that are “about right” for the “average house”), machined and lastly sanded into a floorboard.

However wood is a natural product and if it gets wet, it will swell, and if it dries, it will shrink..

This normally manifests itself across the grain more so than with the grain i.e.across the board rather than along the length of the board. Therefore Solid boards can swell at times of higher humidity (summer) and shrink during periods of lower humidity (winter, when central heating is on).

Clearly one doesn’t want gaps appearing and closing so, to try and mitigate this, Engineered Flooring has been developed.

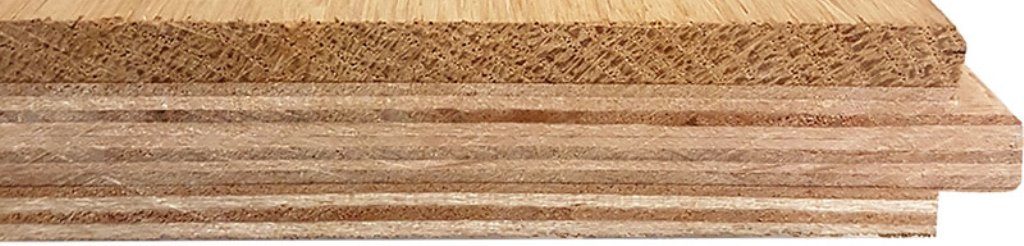

Engineered Oak Flooring Construction

This comprises a “wear layer“ of the desired wood bonded onto a stable substrate. Because the wear layer is thinner than a “proper” solid board, the (now lower) forces can now be contained within the board making it significantly more stable.

Substrates can vary but are frequently made of either plywood or a cross laminated softwood.

This bonded construction means that the finished and machined board is now dimensionally more stable than a solid board, accordingly it is better able to cope with some of the stresses and strains that might be placed upon it by the likes of underfloor heating.

Different constructions have different limitations so a board made of a cross laminated softwood does not have the structural integrity of one built on Plywood so is unsuitable if being laid directly onto joists. However if the floor is fully supported either on a concrete screed, on floorboards or on Chipboard, then the floor only has to contend with forces of compression and a cross laminated construction works perfectly.

A thicker board with a plywood substrate can be laid directly onto joists and has the structural robustness to not need a Chipboard base. In some cases this can represent a cost saving. They are also frequently better where the screed is irregular as they can span any troughs and peaks better.

(This does not mean that surface preparation isn’t necessary. The better the surface preparation, the better the floor!)

Please see our article on “What is an Engineered Wood Floor?”, where we explain the importance of the thickness of the wear layer.

To discuss the matter further, please call Upton Wood Flooring on 01491 628765 or visit us at:

Unit 5,

Manor Farm,

Peppard Common,

Henley on Thames,

Oxon RG9 5LA